At Innovatrombone we are pleased to present this wonderful article by our collaborator Javier Martos.

I want a sackbut. What is the market offering us?

I want a sackbut. What is the market offering us?

In this second article published in Innovatrombone we will discuss what the market offers us when buying a sackbut and the differences between different construction methods.

Therefore, I thought it necessary to show you the basic differences between the sackbut and the current trombone and the constructive differences between the different sackbuts on the market.

This information will serve as a guide for everyone to have an idea of what is offered, being able to choose according to their taste and needs at the time of buying a sackbut.

Of course, in case of any doubt, I will be at your disposal to help you solve it.

Main differences between the sackbut and the modern trombone.

Bell diameter: It is obvious and can be seen with the naked eye that the bell of a sackbut has a much smaller diameter than its current successor. Specifically, the bells of Renaissance sackbuts do not exceed 100 mm and 120 mm for the Baroque ones.

Method of construction of the bell: The bell of a sackbut is forged in a handmade way and that of a trombone is embossed in a lathe. For this reason it is possible to observe in the bell of an original sackbut the blows caused by the hammering in the moment of the forging and not in that of a trombone.

Thickness of the bell walls: The thickness of the bell of a modern trombone is between 0.4 mm and 0.6 mm, while that of a sackbut is less than 0.3 mm, and can reach up to 0.15 mm at the end of the bell.

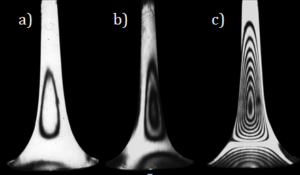

Dr. Richard A. Smith in his research states that a hood with a thickness of 0.3 mm vibrates twice as much as one with a thickness of 0.35 mm. Therefore, one can only imagine the great difference in the behaviour of a bell of a sackbut and its current successor.

Figure 1. Bells of different thicknesses with their nodes.a) 0.5 mm b) 0.4 mm c) 0.3 mm

Garland: As the bell of the sackbut is so slim and thin at the end of it (up to 0.15 mm), a garland is placed on it, which fulfils three functions:

The first is to protect the bell, because of its fragility at the end of it.

The second is an aesthetic function, where the name of the builder, place and year of construction is recorded.

The third and most important is to absorb and regulate the excess vibration generated by such a thin thickness at the end of the hood. When a sackbutter bell vibrates a double node is created, the second node, which occurs at the edge of the bell, makes a “gong” or “echo”; effect (like a church bell). By placing the garland we can cancel this effect, obtaining the vibration of the whole length of the bell and keeping a single node vibrating in the whole of it.

Tuning slide: The sackbut has no tuning slide. The tuning is modified by means of interchangeable tubes of different lengths that are placed between the input of the slide and the mouthpiece. You can also change the pitch by placing a screw between the upper body and the rod.

Slide input diameter: The input diameter of a sackbut is smaller and less conical than that of a current trombone.

Internal slide: the internal slide of the sackbut is handmade from a raw brass sheet and joined by welding, while the rod of a trombone is made from a seamless industrial tube, stretched with a machine, with a widening in its last 10 cm and chrome-plated.

Slide drainage: The sackbut does not have a drain valve to evacuate the condensed water vapor that accumulates inside it.

Lacquered: The sackbut, unlike the modern trombone, is not lacquered, so when the brass is exposed to the air, it creates a protective layer of oxide that makes it darken and has that characteristic color.

Mouthpiece: The mouthpiece of the sackbut is smaller compared to that of the modern symphonic trombone, with a flat edge and the entrance of the tudel more pronounced and cutting. Within what are the sackbut nozzles, it is necessary to distinguish between the Renaissance ones, which are built in several pieces and can be dismantled (Fig. 2 d), and the baroque ones that are manufactured in a single piece.

Figure 2. Photos of a) Renaissance mouthpiece (royal copy) b) Baroque mouthpiece c) Modern mouthpiece d) Dismantled Renaissance mouthpiece (royal copy), representations of interior of mouthpieces e) Renaissance f) Baroque and g) Modern.

2. What does the market offer us in terms of sackbuts?

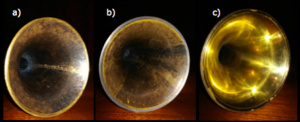

Bell: The market offers us handcrafted forged bells, such as the original ones preserved in museums, and turned bells. The forged bell does not have a uniform stretch and the density of the walls is totally irregular, while the lathe has a helical stretch, which makes the response very different.

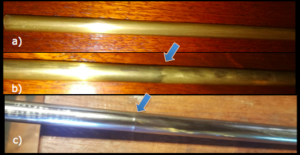

It is possible to distinguish between one and the other because in the handcrafted forging you can see the hammer blows inside, it becomes even more evident passing your finger over the surface (Fig. 3 a) and in the turning you can distinguish the concentric scratches or marks caused by the lathe machine used in its manufacture. The thickness of the walls is so thin that on the outside it is possible to smooth them out so that no marks can be seen, but on the inside it is very risky to do so. For this reason, in a sackbut made with a lathe, they are visible in this area (Fig.3 b).

Whether the hood is dark inside or not does not determine whether it is handcrafted forged or lathe- manufactured, as the inside of the forged one can be polished and not darkened, just as the lathe bell can be darkened.

Figure 3. Pictures of a) Forged handcrafted bell, real copy b) Bell manufactured with lathe c) Bell manufactured with lathe and lacquered.

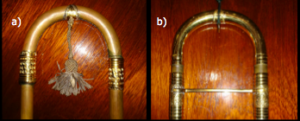

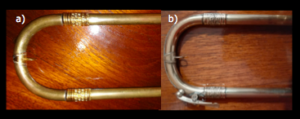

Tuning slide: The different manufacturers offer us sackbuts with tuning slides and without them. Adding a tuning slide to a sackbut involves replacing a 16 cm section of cylindrical tube with a more conical section where the tuning slide would be located.

Most trombonists choose a sackbut with an added tuning slide, first because of the immediate solution it gives at certain times and because this change in its conicity in its morphology gives a different response to the original. This option brings them closer to the sound of the modern trombone, although it must be taken into account that the original sackbut has no tunning slide.

Figure 4. Pictures of a) Curve of the upper body of a real copy sackbut b) Curve of the upper body of a sackbut manufactured with a tuning slide added.

Position of the bell: the sackbuts are built with the bell placed at the height of the fourth position, like the original ones conserved in the museums. There are manufacturers that offer the option to manufacture it in third position for the comfort of trombone players who are accustomed to playing at such distances.

Buying a bell punch at the third position produces an even more pronounced change in sound than adding a tuning pump. The reason is very simple: 5 or 6 centimetres more taper is inserted into the body of the instrument, subtracting them from the total length of the bell.

Figure 5. Comparative photo of a real copy of a punch with the bell in the fourth position and one manufactured with the bell in the third position.

Therefore, adding these two modifications offered by the manufacturers, the general pump and the bell in the third position, changes the percentage in the construction of the cylindrical parts to conical. All this modifies the acoustic characteristics with respect to an original sackbut, which is totally cylindrical until it reaches the bell, thus turning it into a more conical instrument, and therefore closer to the modern trombone.

Slide: Most builders offer what trombonists and most sacabuchistas prefer, an internal slide built from a seamless industrial tube, stretched with a machine, chrome-plated and widened at the end of it (this modification appeared in the nineteenth century). This is far from an original slide, which is built in raw brass from a sheet of brass, welded and without widening at the end, being its construction handmade.

The added changes in the construction and morphology of the internal slide change the sound from that of a handcrafted one. A handcrafted slide is irregular from the beginning to the end, affecting the brightness of the sound, the harmonics and increasing the ductility of the performance to modify timbre and pitch (as with a historic natural trumpet). It is also evident that the chrome of the slide affects the sound, modifying it with respect to a non-chrome slide.

As for the handling of the slide, although a properly worked handcrafted slide can achieve a great fluidity in its movement, it does not achieve the same sensation as the one that presents all the modifications, therefore, the majority of musicians choose the manufactured slide as the modern trombone.

Regarding the widening at the foot of the rod, some builders conceal it by softening the step, making it more conical and progressive, yet it is still not like an original internal rod.

Among the different options offered by builders who are not the artisan option are:

– internal chromed, seamless, stretched and foot-widening industrial slide, like a modern trombone.

-chrome-free, weldless, stretched and foot-widening industrial slide, therefore, although the color of brass suggests it, it is not handcrafted.

-industrial slide made from an industrial cylindrical tube without chrome, without widening at the foot, without welding, perfect, both in diameter and thickness on its walls, but it is still not a slide like that of an original handcrafted sackbut.

Figure 6. Photos of slides a) Hadcrafted b) Industrial unchromed with a smoothed and concealed widening in the foot c) Industrial, chromed and with widening in the foot.

Drain tap: Builders offer different types of drain tap to remove the liquid accumulated on the rod.

The original sackbut lacks it and the action must be performed by removing the external part of the rod to evacuate the liquid content of the same. This change does not significantly modify the sound, although if we want a real copy of the sackbut, they will sell it to us without it.

Figure 7. Pictures of the end of the slide a) Actual handcrafted copy b) Manufactured with drainage.

Lacquer: The sackbuts are not lacquered, although they are offered by the manufacturers if the buyer requires it. Lacquering is one of the changes that most affect the sound of an instrument, since lacquer causes the metal to vibrate less.

Ornamentation: The market offers sackbuts with different degrees of ornamentation, from a real copy of a museum model, to something in-between, to an aesthetics inspired by the period, even without ornamentation. Of course, all this has an impact on the price.

SO, AT THE TIME OF CHOOSING A SACKBUT:

“De gustibus non est disputandum”.

If any trombonist is curious to try all the options in terms of sackbut equipment, they have the opportunity to attend the III International School of Ministrils, which will take place in Requena from 6 to 9 December 2018. Master builder Tony Esparis will lend us a sackbut for those who do not have one. In this way, they will be able to try out sackbuts with different construction options and evaluate what they like most in case they join the historic trombone community in the future

¡SUENE EL LINDO SACKBUT,

Y EL QUE QUIERA ESCUCHAR, QUE ESCUCHE!

Javier Martos Carretero

Acknowledgements: I would like to thank the master builder Tony Esparis, because in order to write this informative article I needed his experience and help. Without it, there would have been some questions left unanswered. Which brings me to another phrase;Whoever wants to build, must be instructed; Thank you, Tony.

We end this publication with an interesting video about the construction of historical trumpets and handcrafted sacks by master builder Geert Jan Van der Heide.

In the video we can see how the master is building a real copy of Lissandro Milanese; trumpet from 1598. Although it is not possible to see how the sackbut is made in its entirety, the construction technique is practically the same.

Bibliografia

GEORGE FISCHER. Henry : “The Renaissance Sackbut and its use today”, The Metropolitan Museum of Art, 1984

VEREECKE, Hannes : “The Sixteenth-Century Trombone. Dimensions, Materials and Techniques” , Centre d’études supérieures de la Renaissance, 2016

Javier Martos Carretero:

http://www.innovatrombone.com/en/trombonists/javier-martos-carretero

Innovatrombone: